In SAP MM/PP MRP as at ECC6.0 EhP8, which of the following are User Definable MRP parameters in MM and PP MRP Configuration ?

(more than one answers)

A) MRP Type.

B) Lot Size Key.

C) Exception Messages.

D) MRP Elements.

E) Special Procurement Key.

.

Answers: A, B, C, E

A) MRP Types are 2-alphanumeric keys provided by SAP but can also be user-defined

IMG - Production - MRP - Master Data - Check MRP Types

MRP type is used to control which procedure is to be used to plan a material and which MRP parameters can be entered when maintaining a material master record. Procedures supported by SAP are eg: MPS, MRP, ROP, Forecasting, Time-Phased Planning (R/3), and DD-MRP (S/4). The MRP Type is assigned to Material Master in MRP 1 data view.

Examples of MRP Types: Standard MRP types include (M0, M1, M2, M3, M4 for MPS), (PD, P1, P2, P3, P4 for MRP), (V1, V2, VB, VM for CBP), (VV for Forecasting), (R1, R2 for Time-Phased Planning).

B) Lot Size Key are 2-alphanumeric keys provided by SAP but can also be user-defined

IMG - Production - MRP - Planning - Lot-Size Calculation

With the lot-sizing procedure you define how the order quantities are determined and it is assigned to the Material Master in MRP 1 data view or in the MRP Area view.

Examples of Lot Size Key: Standard Lot Size Key include (EX, ES, HB for Static Lot Size), (MB, WB for Periodic Lot Size)

C) Exception Messages are 2-alphanumeric keys and can be user-defined as well as set with Priority and Re-Grouped into one of the 8 Exception Message Groupings

IMG - Production - MRP - Evaluation - Exception Messages - Define and Group Exception Messages

There are 8 standard Exception Groups (Selection Group) that Exception Messages can be re-grouped into but both Exception Group and Exception Messages are SAP provided and cannot be user-defined. If a particular exception message is not relevant to your company, select the field No exception message; in the planning run, this exception message is then no longer created for this situation.

Exception Messages can be user-defined but must be created with assignment to an "Internal Exception Message Number (SAP Provided)".

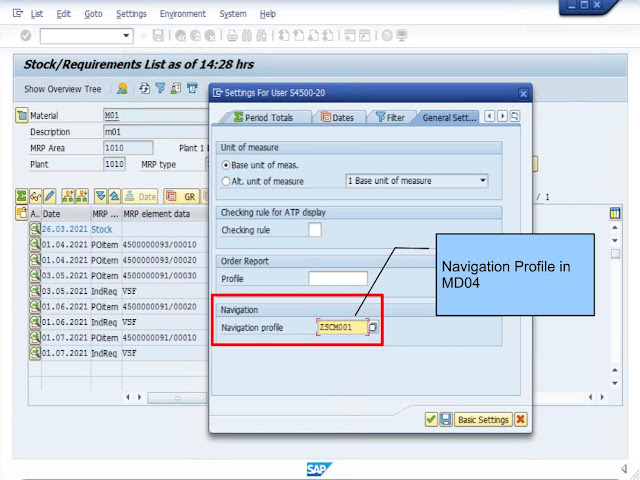

D) MRP Elements cannot be user definable but the Text can be changed.

IMG - Production - MRP - Evaluation - Change Texts for MRP Elements

The MRP elements are displayed in the MRP list and in the stock/requirements list with the short texts defined here; however, MRP elements cannot be created.

E) Special Procurement Type/Key s are 2-alphumeric keys provided by SAP but can also be user-define

IMG - Production - MRP - Master Data - Define Special Procurement Type

Special Procurement Type/Key always used in conjunction with the Procurement Type in the MRP 2 data view. Special Procurement Types are used to fine-tune both internal and external procurements. For example: internal procurement (production related) includes Phantom assembly, Withdrawal in a alternative Plant, Production in another Plant.

For example: external procurement (purchasing related) includes Consignment, Subcontracting, Stock Transfer.

The Special Procurement Type/Key can also be user-defined.