This Blog is mainly on SAP Exam Questions and Selected "How-to" SAP processes

Wednesday, November 29, 2023

Monday, November 27, 2023

Q&A in Class (2023-12-01) S4200

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Storage Location ControlThe above 3 slides are extracts of setup in ECC6 EhP8.

BUT what about S/4 2022 where Storage Location data segment in Material Master MRP4 view is no longer available.

Check the following link to the Blog Post for the Possible Solution:SAP PP - Storage Location MRP (ECC EhP8 vs S/4 2022)

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Limited Production Order creation for a Material

Saturday, November 25, 2023

Thursday, November 23, 2023

SAP Acronyms (Part 11)

Login to a SAP system

comes Monday morning

Q&A in Class (2023-11-22) S4H00

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

PS Internal Work Time Reporting- Create Sales Order with an order item (for example, standard order or repair order) that is account assigned to a WBS element in a customer project.

- The WBS element to be account assigned to the order item on the Account Assignment tab page.

- Enter a Dynamic Item Processor profile (DIP profile) in the tab strip Sales B for the order item.

- If you maintained the Dynamic Item Processor profile in a way so that the system takes the actual cost totals records as the source for the dynamic items.

- The system sorts the dynamic items according to the SD order items and determines the price of the billing request using SD Pricing . In this way the SD Billing will be based on the DIP Items Actual Costs.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

SAP Modules Abbreviations- PS - Project Structuring

- PS - Document integration (PS Text and integration to DMS or Document Management System)

- PS - Notification (Claims)

- PS - Time Scheduling and Capacity Evaluation

- PS - Cost Planning (including Easy Cost Planning)

- PS - Revenue Planning

- PS - Budgeting (including integration to FI-IM Financials - Investment Management)

- PS - Procurement of Materials and Services

- PS - Confirmation of Internal Project Activities

- PS - Billing (including Resource Related Billing)

- PS - Project Progress Analysis

- PS - Period End Closing and Settlement

- PS - Reporting (Structures, Logistics, and Accounting)

Wednesday, November 22, 2023

Monday, November 20, 2023

Saturday, November 18, 2023

Wednesday, November 15, 2023

Sunday, November 12, 2023

Friday, November 10, 2023

Q&A in Class (2023-11-10) S4SD1

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

"Customer - 360° view" FIORI AppYou can find information about this APP in https://fioriappslibrary.hana.ondemand.com/Customer360view-Version2

Somethings to take note in S/4HANA:

- The classic credit management (FI-AR-CR) is no longer available as part of SAP S/4HANA, The functional has been enhanced and replaced by the SAP S/4HANA is SAP Credit Management (FIN-FSCM-CR).

- You can activate/deactivate SAP Credit Management by implementing BAdI UKM_R3_ACTIVATE. SAP S/4HANA 1610 product version and above, SAP Credit Management is implemented as standard, decision to deactivate will turn off the functionality completely.

- In SAP Credit Management (FIN-FSCM-CR), Customer Credit Master data is centralized managed by Business Partner using BP Role: UKM000 Credit Management via "Credit Segment" (New in S/4). The "Credit Control Area" as an Enterprise Structure unit in FI is still active and part of the setup together with "Credit Segment" for Credit Check.

Above is a comparison of SAP IDocs with SAP APIs (Version 1809) for connection between SAP ERP and an EDI solution.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Thursday, November 9, 2023

Wednesday, November 8, 2023

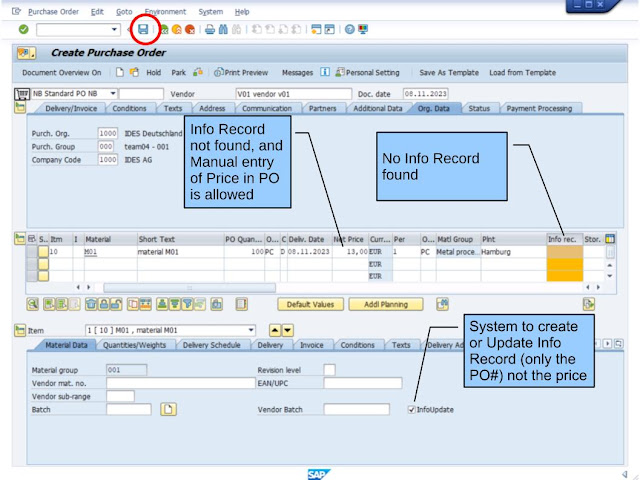

Question no 3982 : Price in Purchasing Info Record

(only one answer)

A) Quotation.

B) Purchase Requisition.

C) Purchase Order.

D) Contract.

E) Scheduling Agreement.

.

Answer: C

A, D, E) Quotation, Contract and Scheduling Agreement allows to generate or update Purchasing Info Record Condition Records.

B) Purchase Requisition has no ability to create or update the Purchasing Info Record.

C) When a Purchase Order is saved and expected to Create the Purchasing Info Record (Info Record does not exist at time of PO creation); for such case, the Price Condition of the PO is not copied over to the Info Record.

Tuesday, November 7, 2023

Monday, November 6, 2023

Sunday, November 5, 2023

Thursday, November 2, 2023

Wednesday, November 1, 2023

Question no 3981 : MRP run with or without Lead Time Scheduling

(more than one answers)

A. When Routing is not found.

B. When BOM and Routing both were not found.

C. When Scheduling mode is "1" Basic dates in MD01 or MD02.

D. When Scheduling mode is "2" and both BOM and Routing were not found.

E. When Scheduling mode is "2" and Routing is not found.

.

Answer: A, C, E

In MD01, MDBT or MD02, the Scheduling selection field allows to shows either "1" or "2":

- "1" Basic date dictates MRP run will use either In-house Production time or Work Scheduling view's Lot size dependent data for scheduling.

- "2" Lead time scheduling dictates the system will try to find a Routing for scheduling but if a Routing is not found then it will revert to use either In-house Production time or Work Scheduling view's Lot size dependent data for scheduling.

_Blogged.jpg)

_Blogged%20(1).jpg)

_Blogged%20(2).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

_0410_S_4CreditMgmtOverview_Blogged.jpg)

_0622_SalesPlan.jpg)