In Configuration, the Strategy can be found using the following menu path: IMG -> Production -> Production Planning -> Demand Management -> Planned Independent Requirement -> Planning Strategy -> Define Strategy

Strategy "20" configuration contents as below:

Notice there are no Requirement Types setup for the Indep. reqmts (or Planned Independent Requirement). As Strategy 20 is basically a MAKE-TO-ORDER strategy; no planned indepenndet requirements are allowed. And therefore Demand is strictly driven from Sales Orders for this particular MTO strategy.

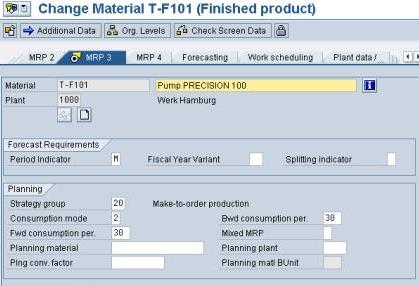

Assignment of the Strategy 20 in the material master as below:

As denoted by the Strategy 20 configuration, Planned Independent Requirement is not allowed for this strategy; demand is driven from Sales Order.

In SAP, MTO strategy creates MTO segmentation for each MTO fulfillment tracking as the screen shot below.

The Stocks of 250 shows the COMMON STOCKS. And immediately below the 250 is the ZERO MTO stocks for the First Sales Order waiting to be fulfilled by the Planning and Execution processes.

Make-to-Order Planned Orders are created by the MRP run.

You can verfiy that it is a MTO Planned Order by checking the details of the Planned Order as below:

As the MTO Planned Order is converted to MTO Production Order below; The X-ref is inherited to the Production Order. (Notice the Sales Order number at almost bottom left corner of the screen shot).

In MTO strategy, the MTO segmentation is carried forward from Planning to Execution until the fullfillment is delivered as depicted in the Stock Requirement List below:

CONLUSION: Strategy "20" is the most basic of SAP's MTO strategy.

APPLICATION: If the lead time of manufacturing the MTO product is 3 months including all the procurement and production lead times AND the customer can place an order 3 months earlier; then this strategy is possible. This is because the strategy only plans for materials after the Sales Order is entered. (Demand is solely driven by Sales Order). Or otherwise, all raw materials must be planned using some other planning so that materials are available when the Sales Order is taken.

CAUTION: Consider alternative MTO strategy provided by SAP or combination of multi-level strategy at different levels of the BOM. These topics will be covered in the future.

.

Strategy "20" configuration contents as below:

|

| From SAP的学习和考试 Learning & Examination |

Notice there are no Requirement Types setup for the Indep. reqmts (or Planned Independent Requirement). As Strategy 20 is basically a MAKE-TO-ORDER strategy; no planned indepenndet requirements are allowed. And therefore Demand is strictly driven from Sales Orders for this particular MTO strategy.

Assignment of the Strategy 20 in the material master as below:

|

| From SAP的学习和考试 Learning & Examination |

As denoted by the Strategy 20 configuration, Planned Independent Requirement is not allowed for this strategy; demand is driven from Sales Order.

|

| From SAP的学习和考试 Learning & Examination |

In SAP, MTO strategy creates MTO segmentation for each MTO fulfillment tracking as the screen shot below.

The Stocks of 250 shows the COMMON STOCKS. And immediately below the 250 is the ZERO MTO stocks for the First Sales Order waiting to be fulfilled by the Planning and Execution processes.

|

| From SAP的学习和考试 Learning & Examination |

After the MRP run:

|

| From SAP的学习和考试 Learning & Examination |

Make-to-Order Planned Orders are created by the MRP run.

You can verfiy that it is a MTO Planned Order by checking the details of the Planned Order as below:

|

| From SAP的学习和考试 Learning & Examination |

As the MTO Planned Order is converted to MTO Production Order below; The X-ref is inherited to the Production Order. (Notice the Sales Order number at almost bottom left corner of the screen shot).

|

| From SAP的学习和考试 Learning & Examination |

In MTO strategy, the MTO segmentation is carried forward from Planning to Execution until the fullfillment is delivered as depicted in the Stock Requirement List below:

|

| From SAP的学习和考试 Learning & Examination |

CONLUSION: Strategy "20" is the most basic of SAP's MTO strategy.

APPLICATION: If the lead time of manufacturing the MTO product is 3 months including all the procurement and production lead times AND the customer can place an order 3 months earlier; then this strategy is possible. This is because the strategy only plans for materials after the Sales Order is entered. (Demand is solely driven by Sales Order). Or otherwise, all raw materials must be planned using some other planning so that materials are available when the Sales Order is taken.

CAUTION: Consider alternative MTO strategy provided by SAP or combination of multi-level strategy at different levels of the BOM. These topics will be covered in the future.

.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.