This Blog is mainly on SAP Exam Questions and Selected "How-to" SAP processes

Wednesday, February 27, 2008

Saturday, February 23, 2008

SAP What is # 4 - What is Strategy 20 ?

In Configuration, the Strategy can be found using the following menu path: IMG -> Production -> Production Planning -> Demand Management -> Planned Independent Requirement -> Planning Strategy -> Define Strategy

Strategy "20" configuration contents as below:

Notice there are no Requirement Types setup for the Indep. reqmts (or Planned Independent Requirement). As Strategy 20 is basically a MAKE-TO-ORDER strategy; no planned indepenndet requirements are allowed. And therefore Demand is strictly driven from Sales Orders for this particular MTO strategy.

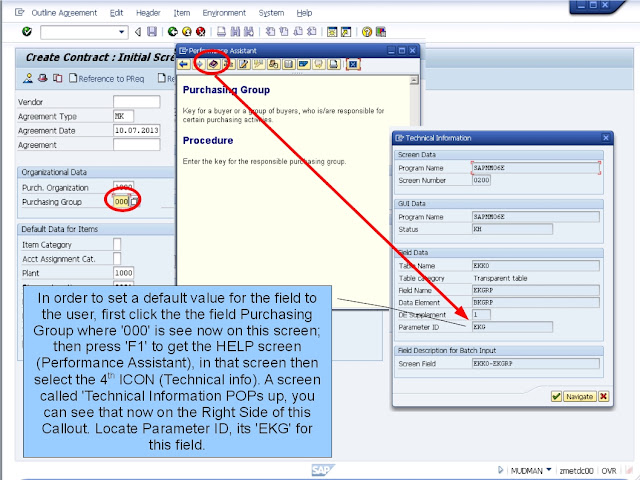

Assignment of the Strategy 20 in the material master as below:

As denoted by the Strategy 20 configuration, Planned Independent Requirement is not allowed for this strategy; demand is driven from Sales Order.

In SAP, MTO strategy creates MTO segmentation for each MTO fulfillment tracking as the screen shot below.

The Stocks of 250 shows the COMMON STOCKS. And immediately below the 250 is the ZERO MTO stocks for the First Sales Order waiting to be fulfilled by the Planning and Execution processes.

Make-to-Order Planned Orders are created by the MRP run.

You can verfiy that it is a MTO Planned Order by checking the details of the Planned Order as below:

As the MTO Planned Order is converted to MTO Production Order below; The X-ref is inherited to the Production Order. (Notice the Sales Order number at almost bottom left corner of the screen shot).

In MTO strategy, the MTO segmentation is carried forward from Planning to Execution until the fullfillment is delivered as depicted in the Stock Requirement List below:

CONLUSION: Strategy "20" is the most basic of SAP's MTO strategy.

APPLICATION: If the lead time of manufacturing the MTO product is 3 months including all the procurement and production lead times AND the customer can place an order 3 months earlier; then this strategy is possible. This is because the strategy only plans for materials after the Sales Order is entered. (Demand is solely driven by Sales Order). Or otherwise, all raw materials must be planned using some other planning so that materials are available when the Sales Order is taken.

CAUTION: Consider alternative MTO strategy provided by SAP or combination of multi-level strategy at different levels of the BOM. These topics will be covered in the future.

.

Strategy "20" configuration contents as below:

|

| From SAP的学习和考试 Learning & Examination |

Notice there are no Requirement Types setup for the Indep. reqmts (or Planned Independent Requirement). As Strategy 20 is basically a MAKE-TO-ORDER strategy; no planned indepenndet requirements are allowed. And therefore Demand is strictly driven from Sales Orders for this particular MTO strategy.

Assignment of the Strategy 20 in the material master as below:

|

| From SAP的学习和考试 Learning & Examination |

As denoted by the Strategy 20 configuration, Planned Independent Requirement is not allowed for this strategy; demand is driven from Sales Order.

|

| From SAP的学习和考试 Learning & Examination |

In SAP, MTO strategy creates MTO segmentation for each MTO fulfillment tracking as the screen shot below.

The Stocks of 250 shows the COMMON STOCKS. And immediately below the 250 is the ZERO MTO stocks for the First Sales Order waiting to be fulfilled by the Planning and Execution processes.

|

| From SAP的学习和考试 Learning & Examination |

After the MRP run:

|

| From SAP的学习和考试 Learning & Examination |

Make-to-Order Planned Orders are created by the MRP run.

You can verfiy that it is a MTO Planned Order by checking the details of the Planned Order as below:

|

| From SAP的学习和考试 Learning & Examination |

As the MTO Planned Order is converted to MTO Production Order below; The X-ref is inherited to the Production Order. (Notice the Sales Order number at almost bottom left corner of the screen shot).

|

| From SAP的学习和考试 Learning & Examination |

In MTO strategy, the MTO segmentation is carried forward from Planning to Execution until the fullfillment is delivered as depicted in the Stock Requirement List below:

|

| From SAP的学习和考试 Learning & Examination |

CONLUSION: Strategy "20" is the most basic of SAP's MTO strategy.

APPLICATION: If the lead time of manufacturing the MTO product is 3 months including all the procurement and production lead times AND the customer can place an order 3 months earlier; then this strategy is possible. This is because the strategy only plans for materials after the Sales Order is entered. (Demand is solely driven by Sales Order). Or otherwise, all raw materials must be planned using some other planning so that materials are available when the Sales Order is taken.

CAUTION: Consider alternative MTO strategy provided by SAP or combination of multi-level strategy at different levels of the BOM. These topics will be covered in the future.

.

Wednesday, February 13, 2008

Question no : 12 MM Purchasing Consumable Scenario

What is the minimum material master data view required for Consumable Scenario Procurement ?

A) Basic, Purchasing, and Accounting view.

B) Basic, Purchasing, Accounting, and Costing view.

C) Purchasing, Accounting, and Costing view.

D) Purchasing, and Accounting view.

E) Purchasing view.

.

A) Basic, Purchasing, and Accounting view.

B) Basic, Purchasing, Accounting, and Costing view.

C) Purchasing, Accounting, and Costing view.

D) Purchasing, and Accounting view.

E) Purchasing view.

.

Tuesday, February 12, 2008

Question no : 11 MM Purchasing Quota Arrangement case study

Consider the following scenario:

... Quota arrangement

Vendor A : Quota = 2 / Quota Alloc.Qty = 1000 / Quota Based Qty = 0

Vendor B : Quota = 1 / Quota Alloc.Qty = 500 / Quota Based Qty = 0

Vendor C : Quota = 1 / Quota Alloc.Qty = 0 / Quota Based Qty = 10000

... All Vendor are valid Sources

The next Procurement Quantity of 2000

Lot sizing rule for the material was set to be Lot for Lot without splitting.

Determine which vendor is selected via Source Determination.

A) Vendor A.

B) Vendor B.

C) Vendor C.

D) Vendor A and Vendor B with quantity split based on the Quota Ratios.

E) No Source can be determined.

.

... Quota arrangement

Vendor A : Quota = 2 / Quota Alloc.Qty = 1000 / Quota Based Qty = 0

Vendor B : Quota = 1 / Quota Alloc.Qty = 500 / Quota Based Qty = 0

Vendor C : Quota = 1 / Quota Alloc.Qty = 0 / Quota Based Qty = 10000

... All Vendor are valid Sources

The next Procurement Quantity of 2000

Lot sizing rule for the material was set to be Lot for Lot without splitting.

Determine which vendor is selected via Source Determination.

A) Vendor A.

B) Vendor B.

C) Vendor C.

D) Vendor A and Vendor B with quantity split based on the Quota Ratios.

E) No Source can be determined.

.

Monday, February 11, 2008

Question no : 10 CO Product Costing Costing Sheet

In SAP CO, The costing sheet used for determining the overhead cost is assigned directly to which of the following CO object ?

A) Valuation Variant.

B) Costing Variant.

C) Bills of Material & Routing Header.

D) Material Master Costing View.

E) Cost Estimate Table.

.

A) Valuation Variant.

B) Costing Variant.

C) Bills of Material & Routing Header.

D) Material Master Costing View.

E) Cost Estimate Table.

.

Sunday, February 10, 2008

Question no : 9 QM Master Data Master Inspection Characteristics

Which of the following objects you can assign directly to the Master Inspection Characteristics in the QM module ?

A) selected set.

B) sampling procedure.

C) document from DMS.

D) inspection method.

E) catalog code group and codes.

.

A) selected set.

B) sampling procedure.

C) document from DMS.

D) inspection method.

E) catalog code group and codes.

.

Friday, February 8, 2008

Question no : 8 PM/CS Master Data BOM and Equipment

In SAP PM/CS, When the company purchased 100 units of equipment of the same model, what is the best method to assign the spare parts to these equipments so that you can pick them up easily in the maintenance/service order later ?

A) Create them as equipment BOM.

B) Create a material BOM for each of the 100 equipment and assigned them individually to each of the equipment as a construction type.

C) Create a hierarchy of equipment with sub-equipments.

D) Create one material BOM and assigned them as construction type to all the equipments.

E) Create a material BOM and call it directly from the maintenance order.

.

A) Create them as equipment BOM.

B) Create a material BOM for each of the 100 equipment and assigned them individually to each of the equipment as a construction type.

C) Create a hierarchy of equipment with sub-equipments.

D) Create one material BOM and assigned them as construction type to all the equipments.

E) Create a material BOM and call it directly from the maintenance order.

.

Monday, February 4, 2008

Question no : 7 PP Master Data BOM types

Which of the following BOM types are relevant for PP MRP run ?

I) Material BOM

II) Sales BOM

III) Equipment BOM

IV) Functional Location BOM

V) Document BOM

A) I only

B) I, II

C) I, II, III

D) I, II, III, IV

E) I, II, III, IV, V

.

I) Material BOM

II) Sales BOM

III) Equipment BOM

IV) Functional Location BOM

V) Document BOM

A) I only

B) I, II

C) I, II, III

D) I, II, III, IV

E) I, II, III, IV, V

.

Saturday, February 2, 2008

Subscribe to:

Comments (Atom)