--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Question: How to plan preventive maintenance for related equipment to the same dates and include the Equipments into a single Maintenance Order ?

Answer: refer to link to the Blog Posts for suggestion solution.

link

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

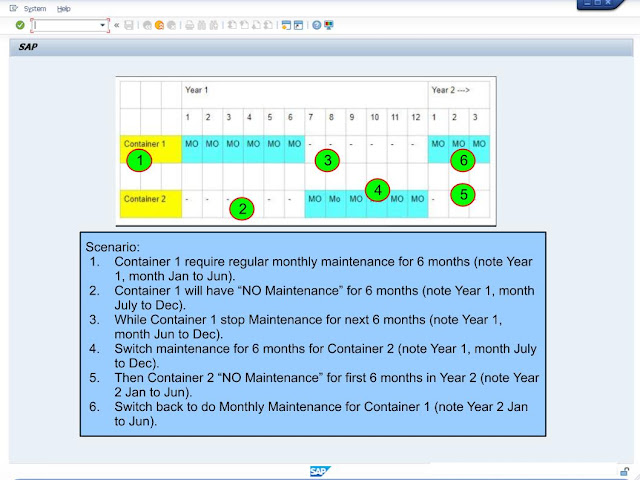

Question: How to setup a scenario where 2 containers which are active 6 months in a rotation manner, only preventive maintenance is only required when the container is active; meaning when Container 1 is active for 6 months will required preventive while Container 2 is non-active and does not required maintenance. Then, in the next cycle (next 6 months), there will be switch to Container 2 to become active and thus required regular preventive maintenance and therefore no maintenance for Container 1 during that period.

Answer: refer to link to the Blog Posts for suggestion solution.

https://froggysap.blogspot.com/2024/10/sap-pm-container-case-study-preventive.html

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Question: Why a user accessing a particular Transaction Codes (eg: MMBE) results in System Hang/Termination, while the same user accessing other Transactions Codes in SAP with no Issues. Interesting any other uses accessing the t-code MMBE has no issues.

Answer: There could have other Technical reasons (Authorization or Basis level) that this scenario is happening for a particular user. From the basic application perspective, it is suggested to look at the following:--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Question: How to Mass Print multiple Maintenance Orders into 1 sheet of Paper?

Answer: In IW32 and IW3D, both transaction code can be used to Print on an entered Maintenance Order (MO). AND although IW38 can be used to Mass Select many Maintenance Orders to perform Print; however, the Print process is still the Shop Papers for each select MOs consecutively one after another.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Question: How to check Change Logs of data fields in the Maintenance Order, eg who added more Components in the MO or change the Header title etc?

Answer: In order to record ALL changes in change LOG for Maintenance Orders, first set the "Change doc" indicator for Plant + Order Type Combination in t-code "OIOE" (Action Log is useful but it does not record ALL change history, only selected changes on certain fields decided by SAP).

After setting in "OIOE", changes for an MO can be accessed in IW32 or IW33 via Extras - Documents for Orders - Changes, from this report, the Change Document number can be found which will show what fields data changed by which user and the time-stamp of changes made. Then, the user can find details of the Change Document via table CDHDR and CDPOS in SE16N.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Question: Tracing PO Qty to Stock and Non-Stock items in the Maintenance Order ?

Answer: For the 2 scenarios:For Non-Stock item - the Booked item in the Maintenance Order is directly linked to the Purchase Order, the item cannot be deleted unless the PO is set deletion flag. Although TECO is allowed, CLSD is not allowed as the PO is pending. In this case, the planner need to decided if the PO should be closed or to be received before settlement process and set "CLSD" status.

For Stock item - the Reservations items book in the Maintenance Order will be subjected to MRP and therefore PR creation (then converted to PO); in MTS scenario, after MRP run, the PR can be traced to the Reservations via "Pegging" in MD04. However, if the Reservations has been deleted by the User (in the MO), there is no more Pegging record for the PR or PO to the original Reservation and in fact, the system will perform auto Pegging to other demand items (other Reservations). It is therefore, no possible to trace the PO created to deleted MO Reservations.

To avoid users to change the operation and spare parts data in the Maintenance Order after the data has been planned by the Planner, the Planner can lock the operation using Digital Signature.

See the link below for how the Digital Signature is executed in a Maintenance Order:click Link: https://DigitalSignature_MO/

- Disallow all other users accessing IW32 and only allow IW33, any changes request Planner to access IW32 to make changes.

- Use Digital Signature to lock the Operation and Components after MO Release.

- Switch-on "Change Log" to "Plant + Order type" in Customizing and download Change Logs in SE16N for table CDHDR and CDPOS for users who have access to IW32 to audit who make changes without informing the planner.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Question: Show the effects of 1:2:2 hierarchy for Time-Based Strategy.

Click https://froggysap.blogspot.com/2024/10/sap-pm-time-based-strategy-122.html

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Question: Setting up for Code Group entry in Measuring Point for Condition-based Maintenance.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Question: Please show the process flow of PM/QM integration in a process flow diagram.

Click Link https://froggysap.blogspot.com/2021/08/quality-management-calibration-planning.html

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

.jpg)

.jpg)

.jpg)

.jpg)

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.